-

*NITROBOOST™ Supplemental Refrigeration*

The new liquid nitrogen-powered NITROBOOST™ supplemental refrigeration systems give manufacturers the ability to maintain target operating temperatures in their existing mechanical tunnel and spiral freezers or blast-style freezers. This avoids production downtime and the related temperature issu...

-

ACCU-CHILL® CBC Continuous Cryogen Injection System

Eliminate seasonal temperature variations. Because flour and other dry, powdered ingredients are typically the major ingredients in your products, bakers find flour and powder cooling to be one of the most effective means of regulating dough temperature. Our in-line cooling system utilizes cryog...

-

ACCU-CHILL® CBC Continuous Cryogen Injection System

Eliminate seasonal temperature variations. Because flour and other dry, powdered ingredients are typically the major ingredients in your products, bakers find flour and powder cooling to be one of the most effective means of regulating dough temperature. Our in-line cooling system utilizes cryog...

-

ACCU-CHILL® Combo Chiller

No Hot Spots - No Frozen Areas A challenge of chilling poultry products that are packed into bulk bins is achieving a consistent temperature throughout – without any hot spots or overcooling. Enter the Linde ACCU-CHILL® ECB Bulk Chiller. This new system automatically distributes product and prec...

-

ACCU-CHILL® CRC Continuous Rotary Chiller

With the ACCU-CHILL® CRC Continuous Rotary Chiller, you can rapidly chill raw or cooked product in whole or cut-up pieces with consistent temperature delivery. The ACCU-CHILL® CRC Continuous Rotary Chiller rotates and gently tumbles food pieces, keeping them separate for maximum cryogen exposure....

-

ACCU-CHILL® In Line Powder/Dry Ingredient Cooling

Eliminate seasonal temperature variations. Because flour and other dry, powdered ingredients are typically the major ingredients in your products, bakers find flour and powder cooling to be one of the most effective means of regulating dough temperature. Our in-line cooling system utilizes cryog...

-

ACCU-CHILL® LXC Bottom Injection System

ACCU-CHILL® LXC cryogenic bottom injection cooling. The ACCU-CHILL® LXC cryogen bottom-injection system is a complete application of various interdependent components and provides rapid, precise temperature reduction during batch mixing or blending. At the heart of the system is the patent-pen...

-

ACCU-CHILL® SC Sauce Chilling

Linde 's ACCU-CHILL SC sauce chilling system quickly cools pizza sauce as it is transported through piping to the assembly area. This rapid chilling speeds up processing times, halts the cooking process and ensures appropriate holding temperatures are maintained.

-

ACCU-CHILL® SC Sauce/Liquid Ingredient Chilling

Rapid In-Line Chilling Before Packaging. Production of cooked custards, fruit fillings & pureés, sauces, soups, gravy, and other liquid foods often requires heating to temperatures as high as 200 degrees Fahrenheit for a specific time appropriate for the product. For many liquid products coo...

-

Already A Reality - Zero-Emissions Mobility

Zero-emissions mobility is a reality with hydrogen refueling technology powered by Linde Hydrogen FuelTech. Our innovative technologies are designed for efficiency and reliability at scale.

-

Bakery Processes

Better bakery processes = better bakery products. Precise temperature control of baking ingredients and finished goods can improve your production and product quality. Our proven systems can be used at each stage of the baking process. Whether it's flour, sugar, raw dough or a fully baked good -...

-

CRYOLINE® CST CryoSaver Tunnel

Proprietary Design = Lower Operating Costs. Incorporating advanced engineered technology into the design of our new CRYOLINE® CST CryoSaver Tunnel results in increased processing efficiency of up to 15% compared to traditional cryogenic freezers. We took each feature into account to extract addi...

-

CRYOLINE® CVT CryoVantage Tunnel Freezer

Cost-Effective and Easy to Clean. The versatile CryoVantage Tunnel freezer is engineered to meet high production needs and efficiently utilize the heat-removing properties of cryogen gas. The freezer model is capable of freezing and chilling a wide variety of products and is a productivity advan...

-

CRYOLINE® Ice Cream Hardening Technology

Technology that’s hard to beat. The CRYOLINE® Ice Cream Hardening Technology is a highly effective processing technology for ice cream and other frozen desserts that allows for an increase in overrun with no decrease in product quality. Our new hardening technology improves ice cream microstruct...

-

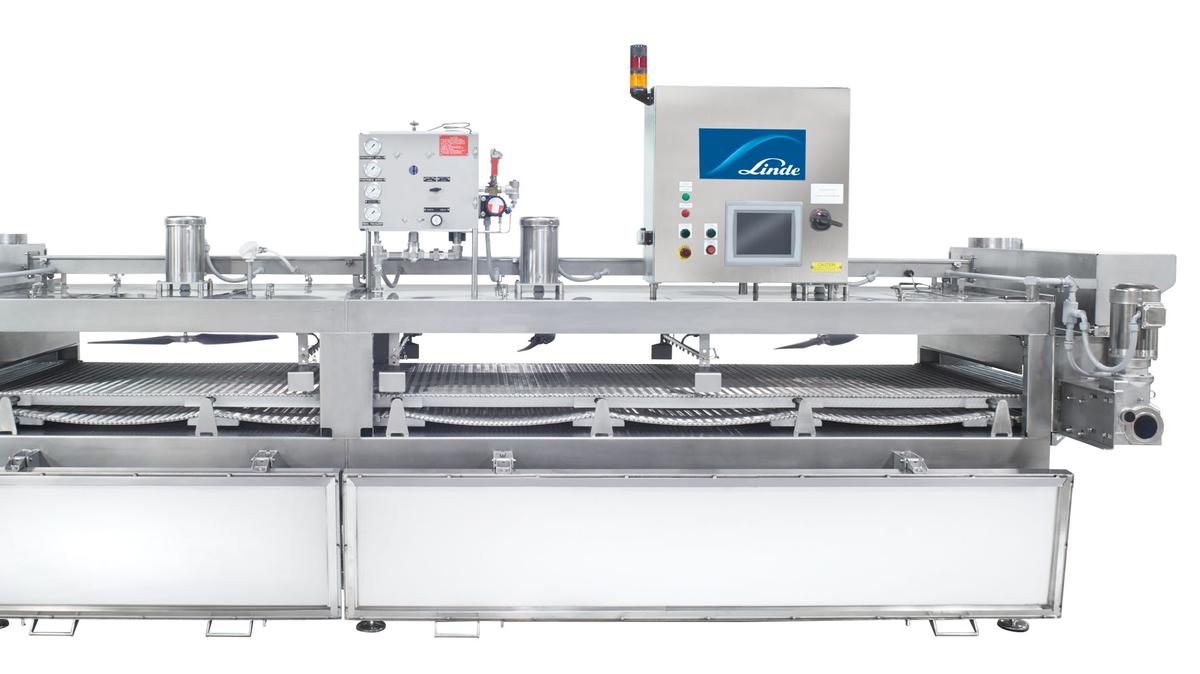

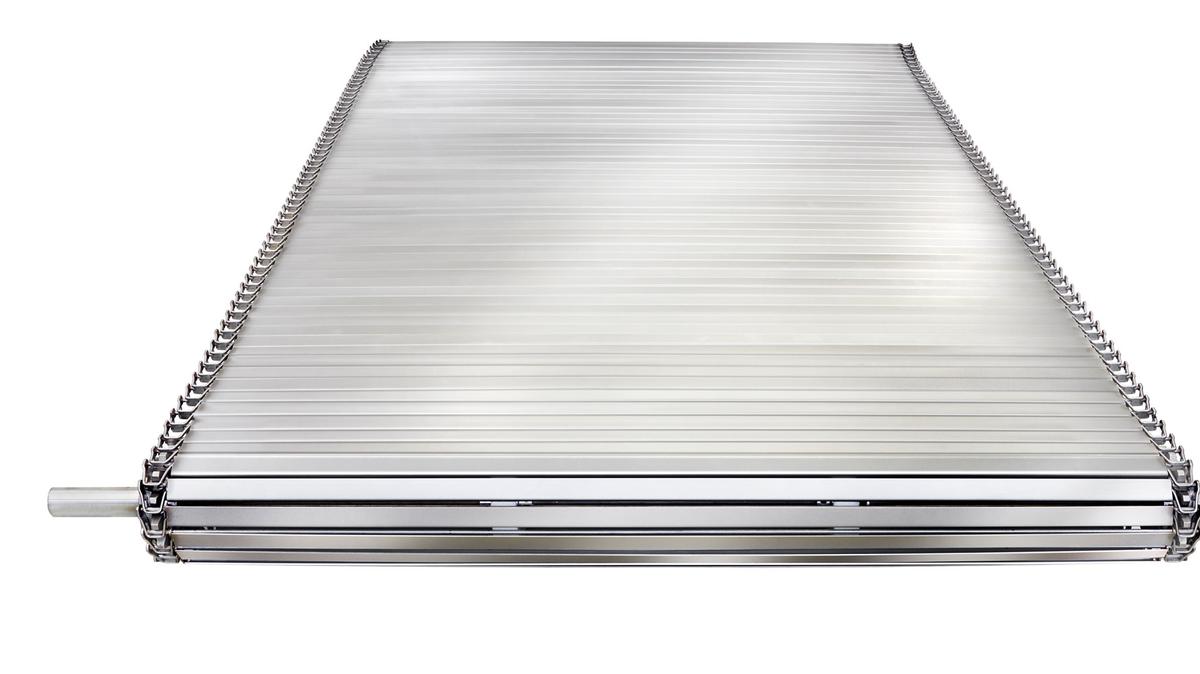

CRYOLINE® PB Plate Belt Freezing System

Improve efficiency with a new solid freezing surface. The Linde CRYOLINE® PB plate belt freezing system was created to rapidly crust freeze wet, marinated, sauced, or brined product to lock in moisture and flavor. The flat, smooth surface of the plate belt provides reduced drip loss and greatly ...

-

CRYOLINE® RC Rapid Crust Freezer

The CRYOLINE® RC is a semi-batch crust freezer built for freezing the surface of larger pieces of food products - such as deli meats - before slicing or dicing. The patent-pending technology uses high-velocity gas to rapidly freeze the product surface, optimizing the use of cryogen while producin...

-

CRYOLINE® UFT Ultra Performance Flighted Freezer

IQF and Improved Sanitation. The CRYOLINE® UFT Flighted Freezer optimizes heat transfer by using cryogen in direct contact with individual food pieces. The internal freezer temperature can reach as low as -150 degrees F depending on conditions and type of cryogen. Loose food products are transp...

-

CRYOLINE® UPS Ultra Performance Spiral Freezer

Get more cold per square foot with the newly improved CRYOLINE® UPS Spiral Freezer. Inside the freezer, a patented cryogen delivery and airflow system greatly enhance cryogen efficiency. This ensures an even temperature across the freezer belt and eliminates incidents of over or under freezing pr...

-

CRYOLINE® UPT Ultra Performance Tunnel Freezer

The success of the CRYOLINE® UPT Tunnel Freezer comes from the perfected delivery of both the cryogenic liquid and vapor circulation. This approach gets much more cooling power from the same amount of cryogen. The ultra-performance tunnel offers improved distribution control of the liquid cryogen...

-

CRYOLINE® UPT Ultra Performance Tunnel Freezer

The success of the CRYOLINE® UPT Tunnel Freezer comes from the perfected delivery of both the cryogenic liquid and vapor circulation. This approach gets much more cooling power from the same amount of cryogen. The ultra-performance tunnel offers improved distribution control of the liquid cryogen...

-

Frozen Beef Patty Process

Linde cooling and freezing gases and equipment can be used to ensure food safety and product quality in frozen meat patties. From the grinding and mixing stage, through to the final freeze, our systems provide rapid and uniform heat removal.

-

Frozen Entree and Appetizer Processes

Linde provides temperature control processes and equipment that can help optimize appetizer and entree quality, increase yield and reduce production time. From individual appetizers and meal components to sauces, gravies and complete meals, Linde has a system to boost your product quality.

-

FROZEN PIZZA PROCESSES

Linde temperature control technologies improve pizza quality and can help you save space, time, and costs. Our freezing and cooling technologies can be used at each stage of the production process to benefit your product and bottom line.

-

Linde Hydrogen Plant in LaPorte, TX

The Linde hydrogen plant in LaPorte, Texas bolsters what was already the world’s largest capacity and distribution system. This plant increases the reliability of our existing network and readies us to meet the rising demand for hydrogen for mobility and beyond.